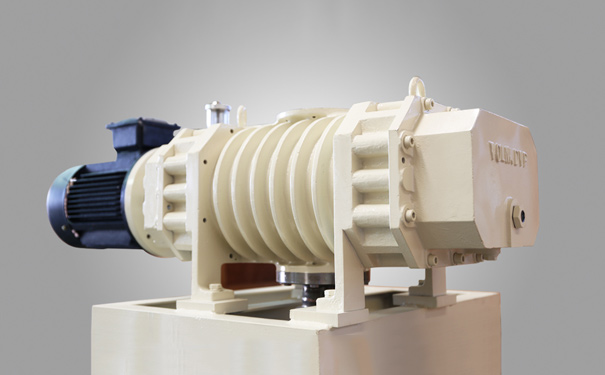

Roots vacuum pump

- Roots vacuum pump

■ Features

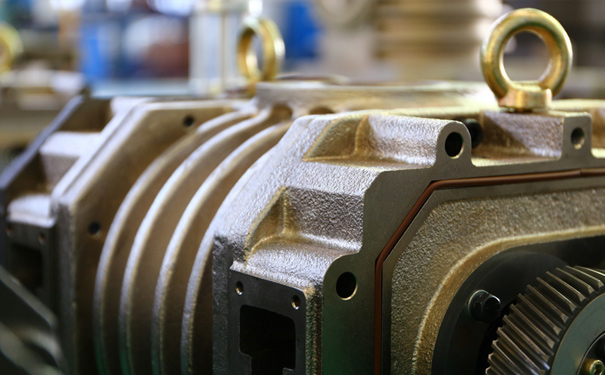

1. Synchronous helical gears are easier to ensure synchronization, to ensure quiet and reliable operation. They are installed on the non-driven side to ensure smooth operation of the pump;

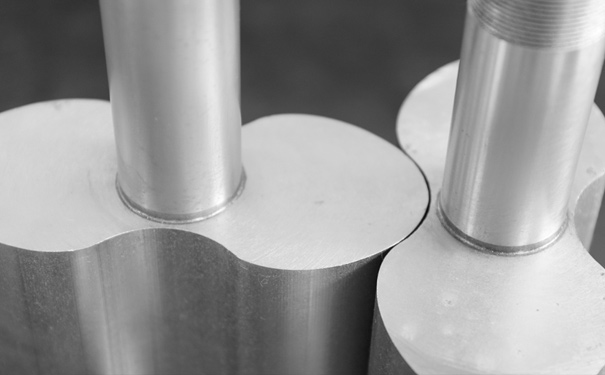

2. Two-leaf Roots rotor: Impeller and shaft are integrally cast. Large shafts can be provided and the risk of impeller damage is reduced;

3. Rotor and internal cavity are coated with Hastelloy, which is suitable for the sucked medium containing corrosive substances;

4. All surfaces of the shaft that are in contact with the seal are polished to reduce seal wear and thus reduce the risk of leakage;

5. Particularly strong casing, suitable for reliable operation under high temperature and high pressure;

6. Both driven and non-driven sides have fuel tanks to ensure better lubrication and being more reliable;

7. The application of the cooling side liner makes the durability of the bearing greatly improved;

8. Much lower maintenance and operation costs.

■ The Introduction of Roots Vacuum Pump

DMB Roots vacuum pump is the equipment with fast pumping rate and lower cost in the vacuum range of 10-1-103 Pa. It can be combined with a variety of vacuum pumps to form vacuum unit, to effectively improve the pumping rate at lower pressure, and to enlarge the range of fore pump’s pumping rate. The combination of dry screw vacuum pump can ensure that the sucked container is cleaner, the system is more reliable. Dynamic balance and leakage test are made for all products before delivering.

The gas is pumped into the chamber through the intake pipeline and discharged from the main vacuum pump to the fore pump’s inlet. As the space (0.2 ~ 0.6mm) between the rotor and machine shell is extremely small when the rotor rotates, this product can achieve clean vacuum discharge, that is, the machine shell and rotor need no use of lubricants. At the same time, because both parts have no touch, the rotor can achieve its semi-permanent use even turns at high speed (up to 3600rpm).This product does not use mechanical seals, long-term chemical effects will not lead to bearing pollution.

■ Applications

● Chemical and pharmaceutical: Vacuum distillation, vacuum dehydration, vacuum dipping, vacuum forming, vacuum freeze-drying

● Electronic semiconductors: LCD, LED, solar cells, semiconductors

● Light industry: Vacuum packaging, lamp manufacturing

■ Technical Data

| Model No. | Suction Volume | Ultimate Pressure | Motor Power | Speed | Inlet Diameter | Outlet Diameter | Liquid Flow | Noise | Weight |

| m3/h(L/S) | Pa | KW | rpm | mm | mm | L/min | dB | Kg | |

| DMB-600 | 500(150) | 0.05 | 2.2 | 2900 | 100 | 80 | 5 | 75 | 200 |

| DMB-1200 | 1000(300) | 0.05 | 4 | 2900 | 125 | 100 | 5 | 75 | 240 |

| DMB-2400 | 2000(600) | 0.05 | 7.5 | 2900 | 160 | 125 | 5 | 75 | 320 |

| DMB-3500 | 3000(900) | 0.05 | 11 | 2900 | 200 | 160 | 8 | 75 | 380 |

| DMB-5000 | 4300(1200) | 0.05 | 15 | 2900 | 250 | 200 | 8 | 75 | 450 |

| DMB-7000 | 6000(1650) | 0.05 | 18.5 | 2900 | 250 | 200 | 15 | 75 | 600 |

| DMB-10000 | 9000(2500) | 0.05 | 22 | 2900 | 300 | 250 | 15 | 75 | 700 |

For more detailed information, please contact us.